Izisetshenziswa Zekhwalithi Nenqubo Yokulawula Ikhwalithi

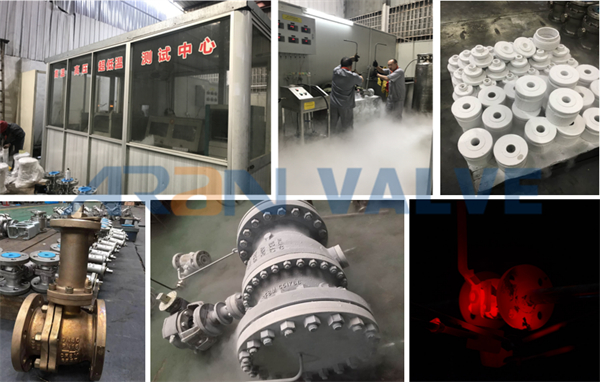

Wonke ama-valve asetshenziswa ngohlelo oluhle lokulawula ikhwalithi, amathuluzi okuhlola athembekile nabasebenzi be-QC abaqeqeshwe kahle, i-ARAN igcina ikhwalithi njengento ebaluleke kakhulu kumakhasimende ethu.

I-ARAN inomnyango wokuhlola wangaphakathi kanye nelebhu egunyazwe evela eceleni yokulawula ikhwalithi ekhethekile, konke ukuhlolwa nokuhlolwa kwenziwa izinto eziqeqeshiwe nezinolwazi.

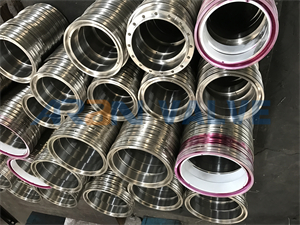

Isikhungo semishini yokulawula ikhwalithi yasendlini, okokuhlola umthelela, ukuhlolwa kokuqina, ukuhlolwa kwe-tensile, ukwakheka kwamakhemikhali kanye nelebhu yempahla eyimishini njll.

Ngemva kwe-oda iUhlelo Lokulawula Ikhwalithi (QCP) kanye Ukuhlola kanyeUkuhlolaUhlelo Lokuhlola (ITP) lungakhishwa ukuze kugunyazwe Iklayenti ngaphambi kokukhiqiza.

1. Isilawuli se-Valve eluhlaza: Ukuhlolwa okubonakalayo nobukhulu, i-PMI, ukujiya kwezindonga, Ukuhlolwa komthelela uma ngesicelo, i-NDE njenge-PT, UT, MT, RT.

2. Ukuhlolwa kwenqubo yomshini we-valve: isheke lobukhulu, ubuso obufakwe ngomshini kanye nokuhlolwa kwezinto ezibonakalayo, isicelo esikhethekile esifana nokuhlolwa kwe-NDE ngesicelo se-oda.

3. Ukuhlanganiswa kwe-valve nokuhlolwa kokusebenza: Ingxenye ngayinye ye-valve ingaphansi kokuhlolwa kwe-hydraulic kanye nomoya ukuhlolwa kokusebenza ngokuvumelana nesicelo esijwayelekile se-oda, isicelo esikhethekile njengokuhlolwa kwe-PAT ngesicelo se-oda.

4. I-Valve Paint, iphakheji kanye nokulethwa.Isicelo esikhethekile njengokuhlolwa komuntu wesithathu ngesicelo se-oda.

Inqubo Yokulawula Ikhwalithi Ejwayelekile

Isilawuli se-Valve eluhlaza: Ukuhlolwa okubonakalayo nobukhulu, isheke lezinto ezibonakalayo, i-PMI, ukujiya kodonga, Ukuhlolwa komthelela uma ngesicelo, i-NDE.

Ukuhlolwa kwenqubo yomshini wengxenye ye-valve: isheke lobukhulu, ubuso obunomshini kanye nokuhlolwa kwezinto ezibonakalayo, isicelo esikhethekile esifana nokuhlolwa kwe-NDE ngesicelo se-oda.

Ukuhlanganiswa kwe-valve nokuhlolwa kokusebenza: Ucezu ngalunye lwe-valve lungaphansi kwe-hydraulic kanye nokuhlolwa komoya ukuhlolwa kokusebenza ngokulandela isicelo esijwayelekile.

I-Valve Paint, iphakheji kanye nokulethwa.

Isicelo Esikhethekile Sokulawula Ikhwalithi

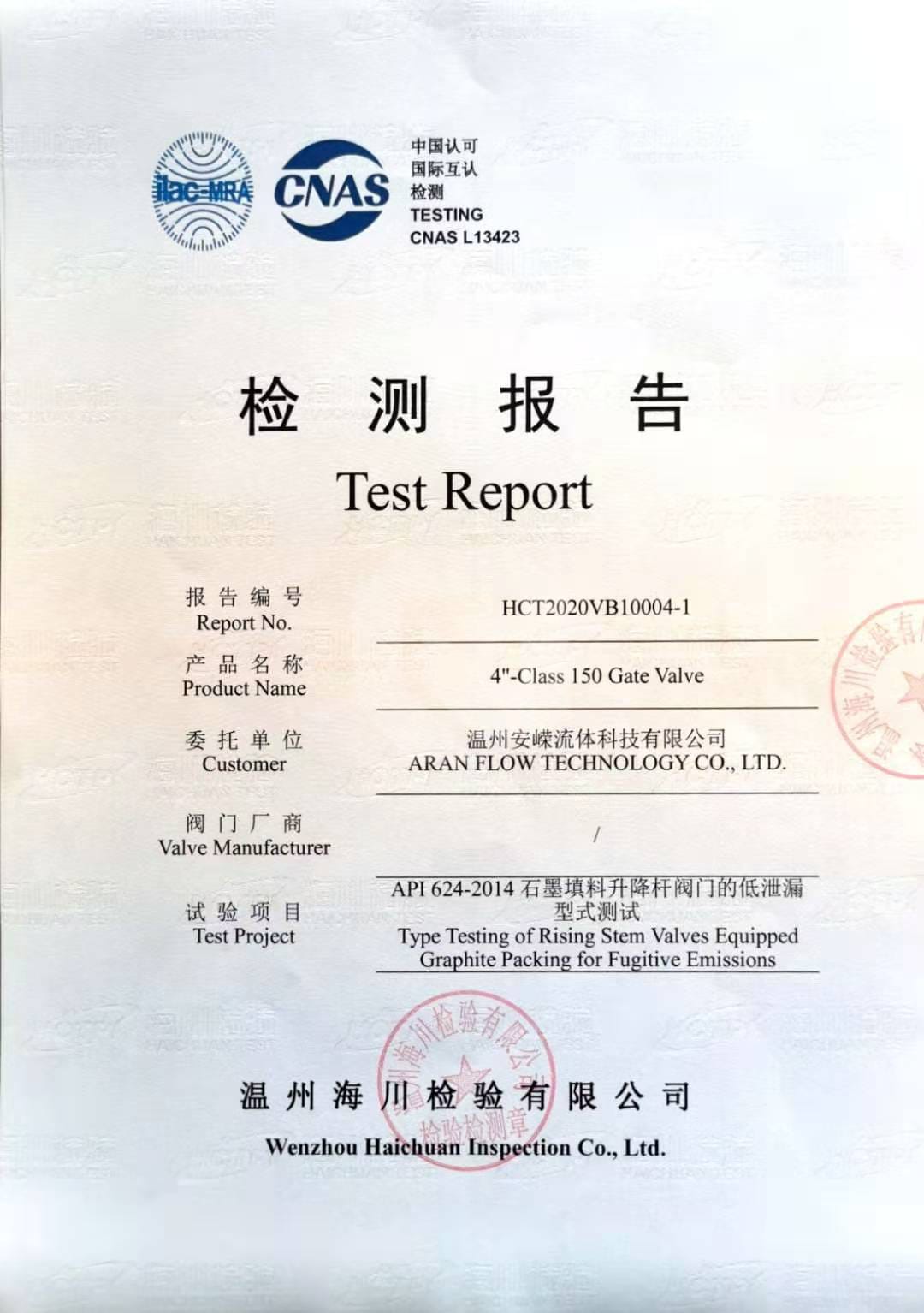

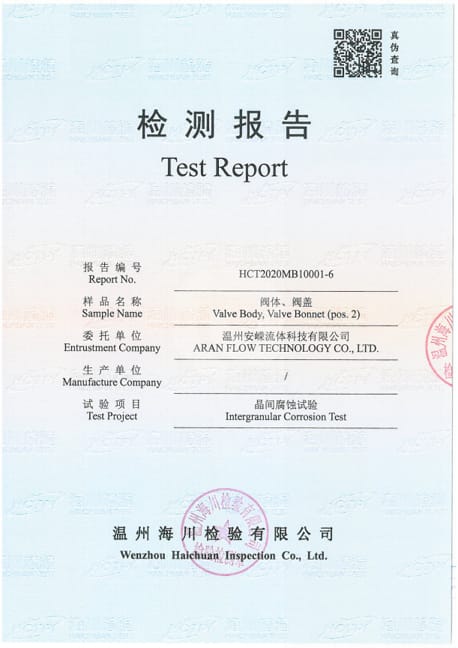

Umbiko wokuhlola okubalulekile kulebhu yezinkampani zangaphandle

- Ukuhlolwa komshini nomthelela

- Ukuhlolwa kokuhlaziywa kwamakhemikhali

- Ukuhlolwa kokugqwala

- isheke Ferrite

- I-Hydrogen inducted cracking test (HIC)

- Isivivinyo sokuqhekeka kwe-Sulphide Stress corrosion

Ukuhlolwa okungabhubhisi (NDE, NDT)

Ukusebenza kwe-VT, PMI, UT, PT kungenziwa endlini kanye nomuntu wesithathu owenza i-UT, PT, MT, RT kanye nobulukhuni, futhi kufaka phakathi izinga leziqu ezizokwenziwa zonke.ezidingweni ze-oda lekhasimende.

- I-VT (Isivivinyo Esibonakalayo)

- I-PMI (Positive Material Identification)

- I-UT (Ukuhlolwa kwe-Ultrasonic)

- I-PT (ukuhlolwa kwe-Penetrant)

- I-MT (ukuhlolwa kwezinhlayiya zikaMagnetic)

- I-RT (ukuhlolwa kwe-X-Ray)

- Ukuhlolwa kokuqina

Ukuhlolwa Kwengcindezi nokusebenza

Amazinga okuhlola afana ne-API 598, API 6D, ISO 5208, EN12266-1, GOST 9544 njll.

- Ukuhlolwa kwe-Functional Test/Torque value

- Ukuhlolwa kweHydraulic / Ukuhlolwa komoya

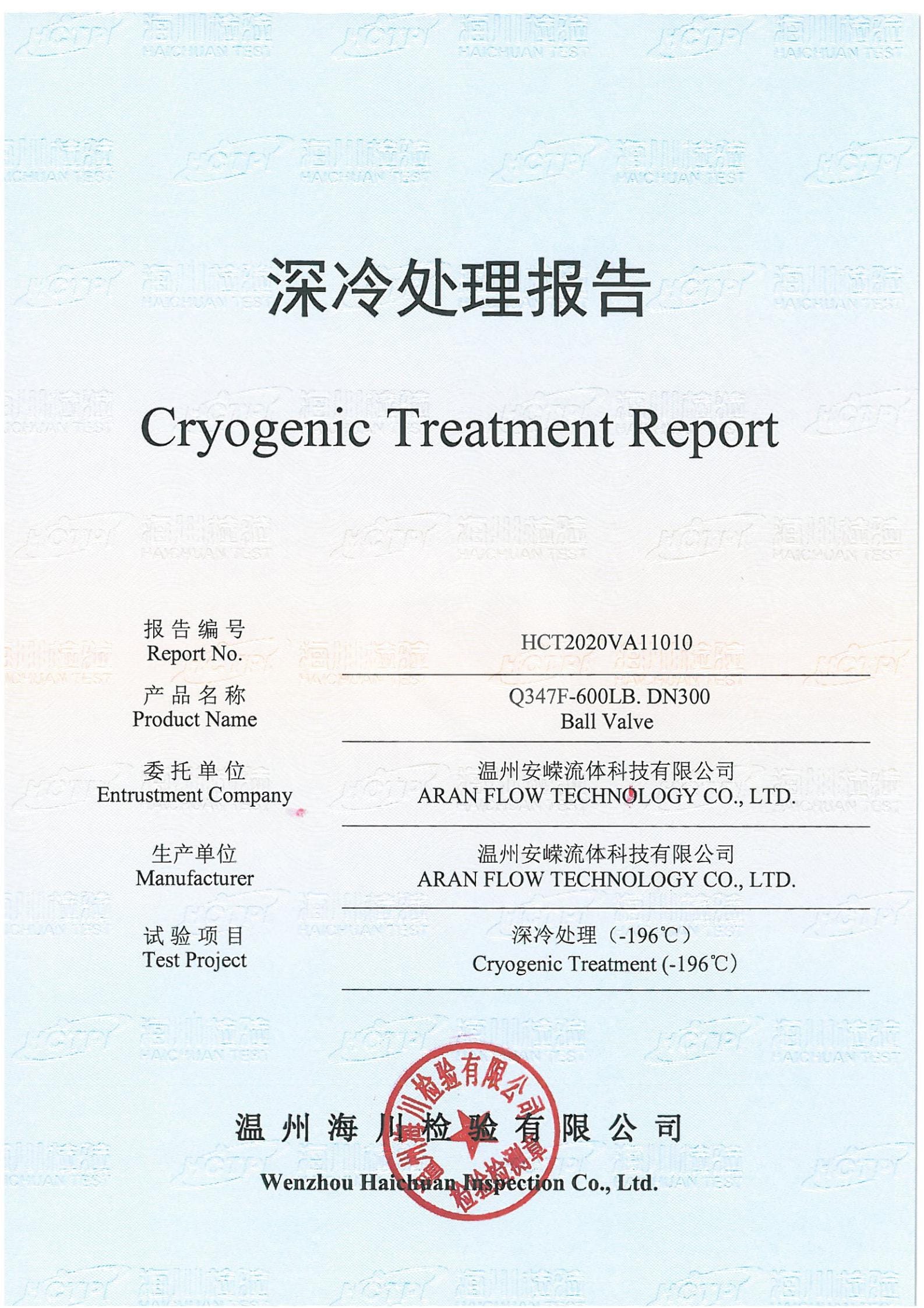

- Izinga lokushisa eliphansi lokuhlola igesi ye-Cryogenic Helium -196°C

- Ukuhlolwa kwezinga lokushisa eliphezulu ngu-600°C

- Ukuhlolwa kwe-Fugitive Emission 15848-1 noma 15848-2

- Ukuhlolwa kokuphepha emlilweni

- Ukuhlolwa kwe-FAT (ukuhlolwa kokwamukelwa kwasefekthri)

- Ukuhlolwa kwe-PAT (ukuhlolwa kokwamukela umkhiqizo)

Ukuhlolwa kwezinga lokushisa eliphansi: izikhungo zelebhu zokushisa okuphansi neziphezulu zokwenza ukuhlolwa kwezinga lokushisa eliphansi noma eliphezulu ngokuhambisana nezidingo ze-oda.Ukuhlolwa kuveza i-valve ekuhlolweni kwezinga lokushisa eliphansi Cryogenic test -196 ℃ noma izinga lokushisa eliphezulu -538 ℃