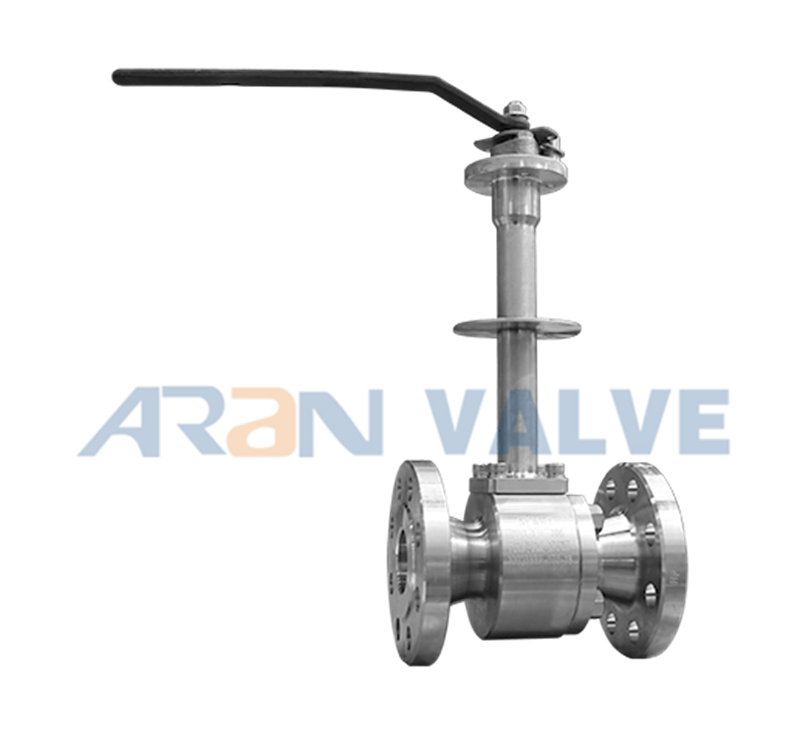

I-LNG Cryogenic Ball Valve Yandisa Isiqu Ngezinga Lokushisa Eliphansi

Isici se-ARAN Cryogenic ball valve design

Ama-valve ebhola e-cryogenic anezakhiwo ezikhethekile zokuklama ezihlangana nokusetshenziswa kokuphepha kwesevisi.

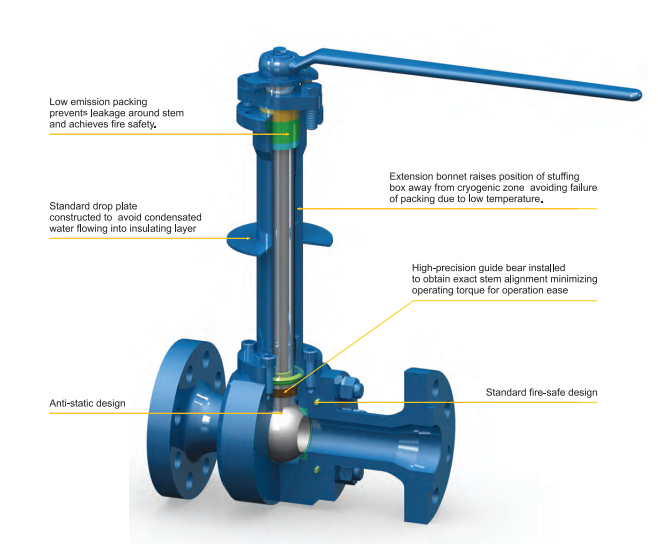

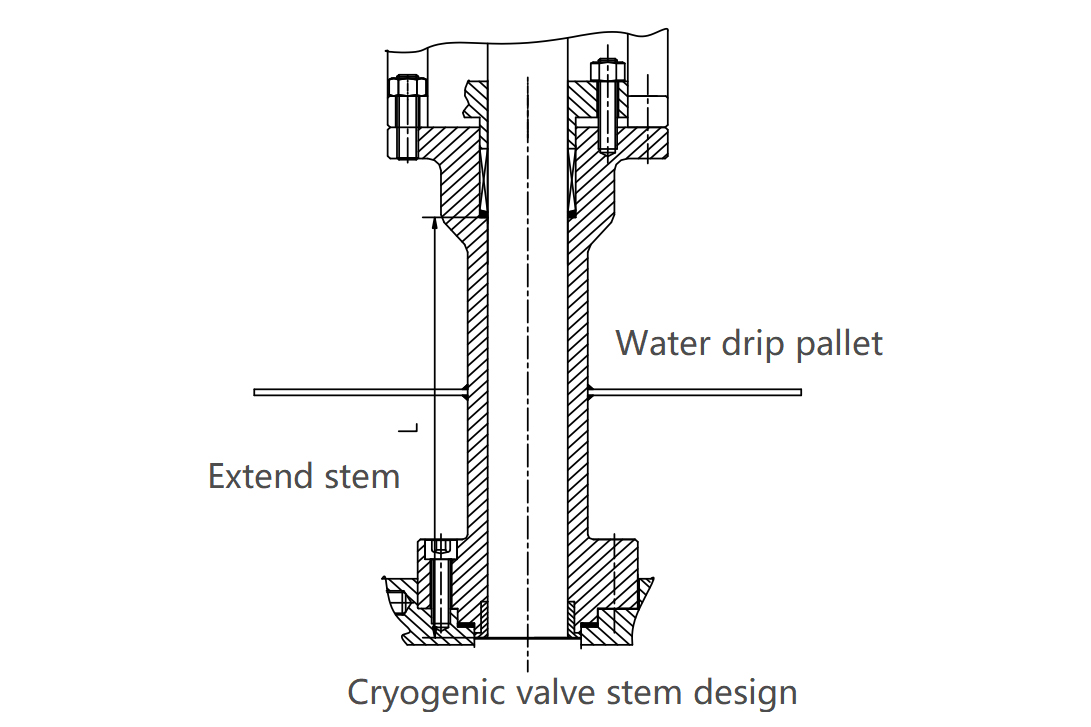

● Amavalvu e-cryogenic aklanywe anesiqu esinwetshiwe kanye nephalethi yokuconsa amanzi esiqwini.

● Iphalethi lokuconsa lingavimbela umhwamuko osemoyeni ukuthi ungancibiliki bese amanzi egeleza aye endaweni yevalvu futhi abe yiqhwa, okubangele ukulimala kwamavalvu. Asetshenziswa ukuze kuqinisekiswe ukusebenza kahle kwebhokisi lokupakisha nokusebenza okuvamile kwamavalvu ebhola.Iphinde inciphise ukushisa okudluliselwa kusuka ngaphandle kuya ngaphakathi kwedivayisi.

● Nweba isibalo sesiqu ngokuya nge-SHELL SPE77/200/BS6364.Isiqu esinwetshiwe esihlobene ne-thermal conductivity of the material, indawo ye-thermal conductivity, i-coefficient yokukhipha ukushisa okungaphezulu kanye nendawo yokukhipha ukushisa.Isiqu esinwetshiwe sivumela isikhala esanele sezinto zokufakelwa futhi siqinisekisa ukuthi isiqu sipakisha umsindo ovalwe ngaphezu kuka-0℃.

● Ukupakisha okungcolile okuphansi, kuvimbela ukuvuza eduze kwesiqu futhi kuqinisekise umlilo uphephile.

Fig. Nweba isiqu ne-Drip Pallet

| Izingxenye Eziyinhloko Material | ||||

| UMZIMBA | I-LCB/LF2 | I-LC3/LF3 | CF8/F304 | CF8M/F316 |

| IBHOLA | F304 | F304 | F304 | F316 |

| STEM | F304 | F304 | F304 | F316/XM-19 |

| ISIHLALO | I-PCTFE/RPTFE/PEEK | |||

| UKUPAKA | PTFE/ GRAPHITE | |||

| I-BOLTING | I-A193 L7/A194 4 | I-A193 B8/A194 8 | I-A193 B8M/A194 8M | |

Njengoba ama-valve ebhola e-cryogenic asetshenziswa ezimweni zokushisa eziphansi, i-valve kumele yomiswe ngokugcwele ngaphambi kokulethwa.Indawo yokuhlola efekthri ngokuvamile i-helium gas. Uma kukhona uketshezi emzimbeni we-valve, uketshezi lungaba sengcupheni yokuba yiqhwa ezingeni lokushisa eliphansi futhi luzokhiqiza ukucindezela ezingxenyeni zangaphakathi zevalvu.Ingcindezi izolimaza ukuvaleka kwama-valve kanye nobungozi bokulimala kwamapayipi.Kuyisizathu futhi ukuthi kungani i-valve ye-valve yebhola e-cryogenic ithathelwa indawo ukuhlolwa komfutho womoya esikhundleni sokuhlolwa kwe-hydraulic esivivinyweni sesayithi.Indawo yokuhlola indawo yokwakha ilinganiselwe futhi i-valve idinga ukomiswa ngokuqinile ngaphambi kokusetshenziswa.

Isicelo

Ama-valve ebhola e-ARAN Cryogenic aqokwe ngokusebenza okuphezulu kakhulu futhi akhiqizwa ngekhwalithi eqinile, angahlangabezana nenkonzo ejwayelekile kakhulu ye-cryogenic, futhi afake isicelo sokuhamba ngokuphepha ukuze kucutshungulwe, kugcinwe, kuhanjiswe kanye nokusatshalaliswa kwe-ethylene, i-Liquid Nitrogen, i-Oxygen, i-LPG, i-Liquefied Natural Gas ( LNG) namanye amagesi anezinga lokushisa eliphansi.

Njengamandla ahlanzekile asebenza kahle futhi agcineke, i-LNG ibonise amathuba entuthuko abanzi kuzo zonke izici zochungechunge lwezimboni.I-valve yebhola ye-Cryogenic iyi-valve edinga kakhulu ku-cryogenic liquid storage kanye nohlelo lwemishini yokuhamba.Inezinzuzo zokushintshwa okuguquguqukayo, ukubeka uphawu okuthembekile, ukuphepha nokuzinza njll.

Ukwelashwa Nokuhlolwa Kwe-Crygenic

Izingxenye ze-valve zesevisi ye-cryogenic zidinga ukwelashwa kwe-cryogenic ukuze uqiniseke ukuthi ukusebenza kwe-valve kuzofanela izinga lokushisa eliphansi.

Ukwelashwa kwe-cryogenic kuyinqubo yokubeka izingxenye ze-valve emazingeni okushisa aphansi nge-nitrogen ephakathi -196 ℃ ukuze kususwe izingcindezi ezinsalela futhi kuthuthukiswe ukumelana nokugqokwa kwezinsimbi.

Ukwelashwa kwe-ARAN cryogenic kwengxenye ye-valve yebhola kanye nokuhlolwa kwe-cryogenic kwe-valve eqediwe.

| Ibanga Lokukhiqiza | I-valve yebhola entantayo ye-Cryogenic |

| Usayizi | I-NPS 1/2″~8″ (50mm~200mm) |

| Ingcindezi | I-ASME Class150~600LBS (PN16~PN100) |

| Amazinga Okukhiqiza | I-API/ANSI/ASME/EN/DIN/BS/GB/GOST |

| Idizayini nekhodi ye-MFG | BS6364/ SHELL SPE 770200 I-valve yokushisa ephansi API 6D/ASME B16.34 /ISO17292/ ISO 14313/BS5351 |

| Ubuso nobuso | I-ASME B16.10,EN558 |

| Qeda Ukuxhumana | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ;BUTT WELD BW ASME B16.25 |

| Ukuhlola & Ukuhlola | ISO 15848/SHELL SPE 77/312 Isivivinyo sokuvuza kwezinga lokushisa eliphansiAPI 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Ikhodi yezinto | I-Low Temperature Carbon Steel -40℃ (ASTM A350 LF2/LF3, ASTM A352 LCB/LCC)I-Low Temperature Carbon Steel -101℃ (ASTM A350 LF3, ASTM A352 LC3)Insimbi engagqwali -196℃ (ASTM A161L/F316 F31 F36 F3) F304L DUAL GRADE, ASTM A351 CF8M/CF3M,CF8/CF3) |

| Ukusebenza | Imanuwali, I-Worm Gearbox, I-activator ye-pneumatic, I-actuator kagesi,I-Hydraulic-electric actuator |

| Umklamo okhethekile | Ama-valve ebhola e-Cryogenic |

| izinga lokushisa eliphansi ukuya ku-196℃ | |

| Nweba ibhonethi ukuze uthole ukupakishwa okuthembekile nokubeka uphawu, nweba ubude be-stem acc.lokushisa | |

| Nweba isiqu nge-drip pallet design acc.lokushisa | |

| I-API6 24 Ukupakishwa kokuphuma kokubaleka okuphansi | |

| Live load API 622 graphite | |

| Isistimu yokusiza ukucindezela komgodi womzimba | |

| Ibhola elintantayo thayipha indlela eyodwa yokuvala | |

| Uhlobo lwebhola le-Trunnion Ukopha kabili kanye ne-block, ukuvala uphawu kabili | |

| Umklamo oyisisekelo | ama-valve ebhola |

| UMLILO UPHEPHILE | I-API 607 |

| IZIBALO ZE-ANTI | I-API 608 |

| Isici sesiqu | I-anti blowout ubufakazi |

| Ukwakhiwa Kwebhonethi | Ibhonethi eboshiwe |

| Uhlobo lwebhola | Ukungena okuseceleni noma ukungena okuphezulu noma i-double block & amabhola ophayo |

| Uhlobo lwe-Bore | Isithukuthezi esigcwele noma Isithukuthezi Esincishisiwe |

| Ongakukhetha ukwenza ngendlela oyifisayo | Ukuthobela i-NACE MR0175, MR0103, ISO 15156 |

| ISO 5211 MOUNTING PAD Shaft engenalutho | |

| Ukushintsha Umkhawulo | |

| Khiya idivayisi | |

| Ukufaneleka kwesevisi ye-ESDV | |

| I-ISO 15848-1 kanye ne-ISO 15848-1 Ukuhlolwa kokuphuma kombaleki okuphansi | |

| Ukuhlolwa okungabhubhisi (NDT) API 6D, ASME B16.34 | |

| Umbiko wokuhlolwa wokuhlolwa komuntu wesithathu | |

| Amadokhumenti | I-EN 10204 3.1 Umbiko wokuhlolwa kwezinto ezibonakalayo we-MTR |

| Umbiko wokuhlolwa kwengcindezi | |

| Umbiko wokulawula okubonakalayo nobukhulu | |

| Iwaranti yomkhiqizo | |

| Imanuwali yokusebenza kwe-valve |