I-Hard Metal Ehlezi I-Ball Valve Trunnion Egibele I-ISO5211 I-Flange Ephezulu

Amavalvu Ebhola Ahlezi Ensimbi

I-valve yesihlalo sensimbi ikhethelwa indawo esindayo efana nezinhlayiya eziqinile, ukuhuzuka, izinga lokushisa eliphezulu noma isigaba somfutho ophezulu noma nanoma ubani onalesi simo esishiwo sihlanganisiwe, ipayipi elivamile njengamakhemikhali amalahle, i-pulp & paper kanye nendawo yokuhluza uwoyela ongahluziwe njll. I-valve yebhola lesihlalo ikhombisa ukusebenza okuhle kokuvala, isevisi yesikhathi eside, itorque ephansi kanye nokuncipha kwengcindezi ngokuqhathaniswa kusevisi eshiwo ngenhla.Ivalvu evamile njengeglobhu kanye ne-valve yesango ayikwazanga ukuhlangabezana nesimo esinjalo sokusebenza, ngakho-ke i-valve yesihlalo sebhola yensimbi ikhulisa izidingo ezengeziwe zesevisi enzima.

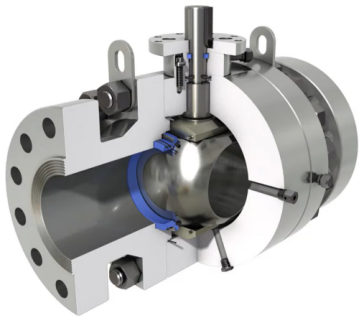

● Ibhola le-Trunnion linesiqu esiphezulu kanye negayidi ye-trunnion ephansi enciphisa i-stem torque

● Ukuvalwa kwegraphite phakathi kwesihlalo nesiqu esifanele izinga lokushisa eliphezulu

● Isihlalo sasentwasahlobo se-Piston Inconel X750 silinganisela ukucindezela kwesihlalo

● Ukopha kabili nokuvimbela uhlelo

● Isivikelo somlilo nesinqamuki ukuphuma kwesiqu

● Ivalvu yesihlalo sesihlalo se-trunnion ngokuvamile inokwakheka kokuvala isihlalo ekugcineni kwebhola lokungena.Lezi zihlalo ezimbili zinqamule okuphakathi ngokuzimele endaweni yokungena kanye nokuphuma ekugcineni ukuze kuzuzwe umsebenzi wokuvimba kabili.Lapho i-valve yebhola ivaliwe, ngisho noma iziphetho zombili zokungena nokuphuma kwe-valve zicindezelwa ngasikhathi sinye, umgodi ophakathi we-valve kanye namaphaseji emikhawulweni yomibili ingavinjelwa komunye nomunye, futhi okuphakathi okusele ngaphakathi. umgodi ophakathi ungakhishwa ngama-valve okusiza.

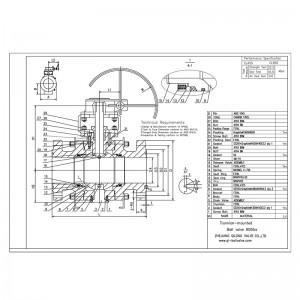

I-FIG.Uhlobo lwevalvu yebhola ye-Trunnion

isihlalo se-valve yensimbi ehlezi sivulekile futhi isihlalo sivale umdwebo wesigaba.

Isihlalo sivuliwe

Isihlalo sivaliwe

I-ARAN Metal Metal Seated Ball Valves asetshenziswa kakhulu ezimweni ezinzima zesevisi njengokugqwala okuphezulu noketshezi lwenqubo yokuguguleka enezinhlayiya eziqinile namazinga okushisa aphezulu noma umfutho ophakeme, izimo ezinjalo ivalve yebhola ehlezi ethambile ayikwazanga ukuqina ngenxa yomehluko wezihlalo.Ngesicelo sombuzo, ulwazi lwe-valve medium kanye nezinga lokushisa lubaluleke kakhulu kunjiniyela wezokuthengisa wakwa-ARAN ukukhetha uhlobo olulungile lwemodeli.

| Ibanga Lokukhiqiza | I-Metal Seat Ball Valves |

| Uhlobo lwezinto | Insimbi eyakhiwe noma i-Cast steel: i-carbon steel, i-LTCS, i-alloy steel, insimbi engagqwali, i-duplex steel, ithusi, i-Inconel, i-Hastelloy, i-Monel, i-Incoloy njll. |

| Ikhodi yezinto | WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L |

| Uhlobo lwesihlalo | I-Metal ihlezi okokunamathela okuqinile njenge-CRC/TCC/STL6/Ni60/STL |

| Usayizi | I-NPS 2”~24” (50mm~600mm) |

| Ingcindezi | I-ASME Class150~2500LBS (PN16~PN420) |

| Ukusebenza | Imanuwali, I-Worm Gearbox, I-activator ye-pneumatic, I-actuator kagesi,I-Hydraulic-electric actuator |

| Working Medium | WOG |

| Izinga lokushisa lokusebenza. | Ubukhulu 540 ℃ |

| Amazinga Okukhiqiza | I-API/ANSI/ASME/EN/DIN/BS/GOST |

| Idizayini nekhodi ye-MFG | I-API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Ubuso nobuso | I-ASME B16.10,EN558 |

| Qeda Ukuxhumana | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ;BUTT WELD BW ASME B16.25 |

| Ukuhlola & Ukuhlola | I-API 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Umklamo oyisisekelo | |

| UMLILO UPHEPHILE | I-API 607 |

| IZIBALO ZE-ANTI | I-API 608 |

| Isici sesiqu | I-anti blowout ubufakazi |

| Uhlobo lwebhola | Ukungena eceleni |

| Uhlobo lwebhola elintantayo | ukubekwa uphawu ngendlela eyodwa noma ukubekwa uphawu kabili |

| Uhlobo lwebhola le-Trunnion | Wopha kabili futhi uvimbele |

| Uhlobo lwe-Bore | Isithukuthezi esigcwele noma Isithukuthezi Esincishisiwe |

| Ukwakhiwa Kwebhonethi | Ibhonethi eboshiwe noma ibhonethi eshiselwe ngokugcwele |

| Ongakukhetha ukwenza ngendlela oyifisayo | Ukuthobela i-NACE MR0175, MR0103, ISO 15156 |

| ISO 5211 MOUNTING PAD Shaft engenalutho | |

| Ukushintsha Umkhawulo | |

| Khiya idivayisi | |

| Ukufaneleka kwesevisi ye-ESDV | |

| Ukuvalwa kwe-Bidirectional ukuvuza kwe-Zero | |

| Nweba isiqu ukuze uthole isevisi ye-cryogenic | |

| Ukuhlola okungabhubhisi (NDT) kuya ku-API 6D, ASME B16.34 | |

| Amadokhumenti | Amadokhumenti okulethwa |

| I-EN 10204 3.1 Umbiko wokuhlolwa kwezinto ezibonakalayo we-MTR | |

| Umbiko wokuhlolwa kwengcindezi | |

| Umbiko wokulawula okubonakalayo nobukhulu | |

| Iwaranti yomkhiqizo | |

| Imanuwali yokusebenza kwe-valve | |

| Umkhiqizo wemvelaphi |

Ipayipi likawoyela negesi

Ama-valve ebhola ahlezi ensimbi aklanyelwe ukuhlangabezana nezidingo ezibalulekile zesevisi embonini kawoyela negesi.Lezi zimboni zidinga izigxivizo eziqinile ezinokwethenjelwa ezinamathuba aqandayo okuvuza.Ukukhiqiza kwe-QL

Ukukhiqiza amandla

Ama-valve ebhola ahlezi ensimbi e-QL ahlinzeka ngezixazululo ezinokwethenjelwa, ezongayo nezesikhathi eside zezicelo ezibalulekile ezitshalweni zamandla.Ngokuqina kwesihlalo esiqinile nokulungiswa okuncane ama-valve esihlalo sensimbi ye-QL angama-valve afanelekile ezicelo zemboni yamandla.

I-Petrochemicals

Izimo zokusebenza ezibucayi, ukusebenza okubalulekile kokuphepha, nama-asidi abolayo ezimbonini zokucubungula i-petrochemical zidinga amavalvu ensimbi ahlezi.Ukusebenza okuphakeme kanye nobulukhuni bobuso bensimbi ye-QL ehlezi i-valve yebhola yokushisa ephezulu izoqinisekisa ubuqotho nokuphepha komsebenzi wonke.

Imboni yezimayini

Isimo sokucubungula esinzima semboni yezimayini singadala umonakalo omkhulu kumavalvu.Amavalvu ebhola e-QL ahlezi ngensimbi amelana nokuhuzuka futhi izihlalo ezinamathelayo ezikhethekile zihlala isikhathi eside.Zinhle ekusetshenzisweni okufana nemigqa yokukhipha umoya, ukuhlukaniswa kwepompo ye-slurry kanye nomjovo we-asidi.

Imboni ye-Pulp nephepha

Imboni ye-pulp nephepha idinga ukuhlukaniswa okungavuzi lutho kanye nezinto eziyingozi.Akukhona nje kuphela ukuthi ama-valve ethu ahlezi ensimbi ahlinzeka ngokuhlukaniswa okuthembekile, futhi aqukethe i-coating ekhethekile yokuqina.Lokhu kuthuthukisa ukuguga kwazo, ukugqwala nokumelana nokuguguleka, ngaleyo ndlela kwandise impilo yazo yesevisi.